Why are Condenser Plates Essential in Various Industries

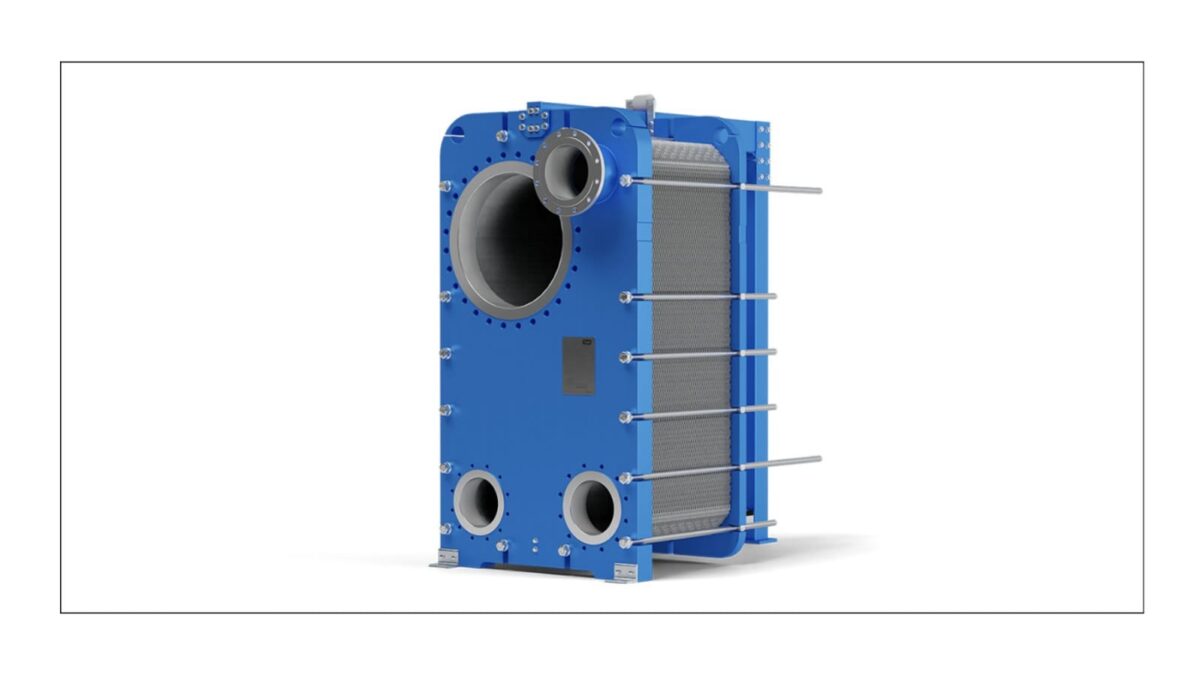

Condenser plates play an important part in heat transfer processes and are used in a variety of industries. These plates are used for a variety of purposes, including refrigeration, power generation, and desalination, among others. Condenser plates are also manufactured in accordance with sustainable methods. Condenser plates are important components of environmentally friendly manufacturing processes because they improve heat transfer efficiency and assist reduce energy consumption and greenhouse gas emissions. In this blog, we will look at the importance of condenser plates in many sectors and how they might improve efficiency and sustainability.

Applications of Condenser Plates :

- Refrigeration: In refrigeration frameworks, condenser plates work with the exchange of intensity from the refrigerant to the general climate. This cycle is fundamental for keeping up with the ideal temperature inside refrigeration units, guaranteeing the protected stockpiling of transitory products in enterprises, for example, food handling, drugs, and substance stockpiling.

- Power Generation: Condenser plates are vital to drive plants, where they convert steam once more into water after it has gone through a turbine. This buildup interaction discharges heat energy used to produce power. Condenser plates assume an essential part in proficiently moving intensity, guaranteeing ideal power age productivity.

- Desalination: In desalination plants, condenser plates remove heat from seawater, permitting it to gather and be gathered as freshwater. This cycle is basic for tending to water shortage challenges in seaside districts and guaranteeing a maintainable wellspring of freshwater for different ventures and networks.

- Chemical Processing: Condenser plates find application in chemical processing industries for cooling and condensing gases and vapours. They facilitate the removal of heat from chemical reactions, ensuring process efficiency and product quality.

- Sustainable Manufacturing: By enhancing heat transfer efficiency, condenser plates help reduce energy consumption and minimize greenhouse gas emissions in various industries. This makes them integral components of sustainable manufacturing practices, aligning with global efforts to reduce carbon footprints and promote environmental sustainability.

- Pharmaceuticals: Condenser plates play a vital role in pharmaceutical industries, where they are used in refrigeration units to store temperature-sensitive medications and vaccines.

- HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems in buildings utilize condenser plates to transfer heat and maintain comfortable indoor temperatures.

- Environmental Control: Condenser plates are also used in environmental control systems, such as air scrubbers, to remove contaminants from air or water by condensing them for easier disposal.

Conclusion :

Condenser plates play an important part in heat transfer operations in a variety of sectors. Condenser plates are essential for maintaining appropriate temperatures and guaranteeing efficient operations in a variety of applications, including refrigeration, power generation, desalination and chemical processing. Furthermore, condenser plates help to promote sustainable manufacturing practices by increasing heat transfer efficiency while decreasing energy usage and greenhouse gas emissions.

As industries continue to prioritize sustainability and environmental responsibility, the significance of condenser plates in accomplishing these objectives cannot be emphasized. Industries that invest in efficient heat transfer technology such as condenser plates can not only improve operational efficiency but also contribute to a greener, more sustainable future.