Sheet Metal Services

Services offered:

- Laser cutting

- CNC bending

- Shearing

- Fabrication

DNE Bystronic Fibre Laser Cutting Machine

- Bed size: 6.5 metre x 2.5 metre

- Max. cutting thickness: 25mm MS, 20mm SS

- 6mm for Brass, Aluminium & copper

CNC Bending Machine

- Size: 6.1 metre

- Max: bending thickness: 16mm MS

- Tonnage: 700 ton

CNC Shearing Machine

- Size: 6.3 metre

- Max. shearing thickness: 12mm MS

Amada CNC Shearing Machine

- Size: 3 metre

- Max. Shearing thickness: 10mm MS

Amada CNC Bending machine

- Size: 3.1 metre

- Max. bending thickness: 6mm MS

- Tonnage: 150 ton

Sheet Metal Services have become an integral part of modern manufacturing, offering precision and versatility in the fabrication of a wide range of products. With expertise in laser cutting, CNC bending, shearing, and fabrication, our company is dedicated to delivering high-quality solutions tailored to meet the diverse needs of industries such as automotive, aerospace, electronics, and construction. In this article, we will explore the key aspects and benefits of our comprehensive sheet metal services.

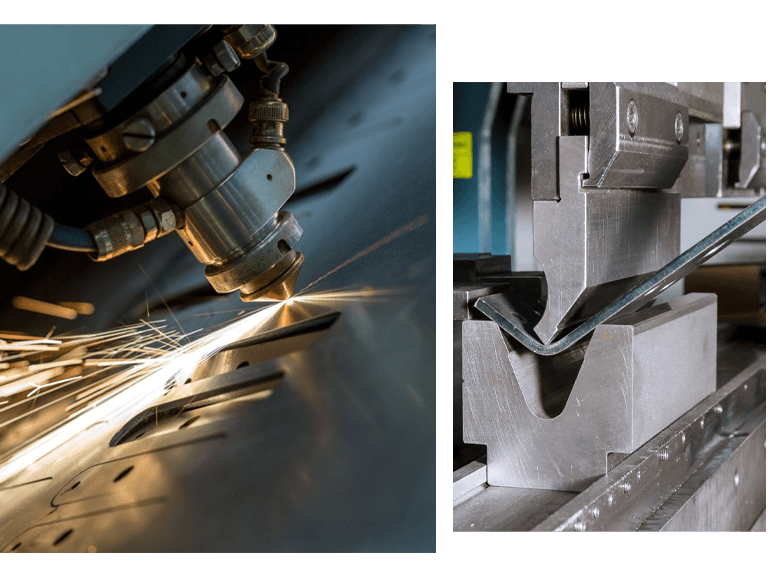

Laser Cutting: Precision and Versatility Combined:

Laser cutting is a fundamental aspect of our sheet metal services, enabling precise and intricate cutting of various materials with exceptional speed and accuracy. Our state-of-the-art laser cutting machines utilize advanced laser technology to precisely follow programmed designs, resulting in clean and burr-free cuts. With the ability to handle a wide range of materials, including stainless steel, aluminum, and mild steel, our laser cutting services provide unparalleled versatility and precision for your specific application requirements.

CNC Bending: Complex Shapes with Perfect Accuracy:

CNC bending is a crucial process in sheet metal fabrication, allowing us to transform flat sheets into complex three-dimensional shapes with utmost accuracy. Our advanced CNC bending machines utilize computer-controlled hydraulic press brakes, ensuring precise bending angles and dimensions. With the ability to handle various sheet thicknesses and material types, our CNC bending services enable the creation of intricate components, enclosures, brackets, and other custom-formed parts, meeting your exact specifications.

Shearing: Clean and Accurate Cutting:

Shearing is a fundamental process in sheet metal fabrication, providing clean and accurate cutting of flat metal sheets. Our shearing services utilize high-precision shearing machines that can handle a range of materials and thicknesses. With our experienced operators and state-of-the-art equipment, we ensure that your sheet metal is precisely cut to the required dimensions, meeting tight tolerances and delivering superior edge quality. Whether you need large-scale production runs or small custom cuts, our shearing services provide efficient and precise results.

Fabrication: Tailored Solutions for Your Needs:

Sheet metal fabrication is where our expertise truly shines. Our skilled fabricators have the knowledge and experience to transform sheet metal into functional and aesthetically pleasing products. From concept to completion, we work closely with our clients to understand their specific requirements and deliver customized solutions. Whether it’s prototyping, production runs, or complex assemblies, our fabrication services encompass welding, fastening, finishing, and assembly, ensuring that your sheet metal components are fabricated to the highest standards of quality and precision.

Quality Assurance and Timely Delivery:

At Sheet Metal Services, we place great emphasis on quality assurance throughout our processes. Our dedicated team follows strict quality control protocols, conducting thorough inspections at every stage to ensure that the final products meet or exceed your expectations. Moreover, we understand the importance of timely delivery in today’s fast-paced industry. With efficient production planning and streamlined workflows, we strive to meet your project deadlines without compromising on quality or precision.