Forming Shop

Services offered:

- Sheet Rolling

- Sheet pressing

- Hot forming

- Heavy Fabrication

Sheet Rolling Machines

Sheet Rolling Machines play a crucial role in the metalworking industry, offering precision and efficiency in the process of rolling and forming various types of sheet metal. These versatile machines are designed to handle a wide range of materials and thicknesses, allowing for the creation of cylinders, cones, and other curved or cylindrical shapes with exceptional accuracy. In this article, we will explore the key features and benefits of Sheet Rolling Machines and their significance in the manufacturing and fabrication processes.

Pressing Machines

Pressing Machines play a vital role in the metalworking industry, providing power and precision for a wide range of pressing, punching, and forming operations. These versatile machines are designed to handle various materials and thicknesses, allowing for the efficient production of components with exceptional accuracy. In this article, we will explore the key features and benefits of Pressing Machines and their significance in modern manufacturing processes.

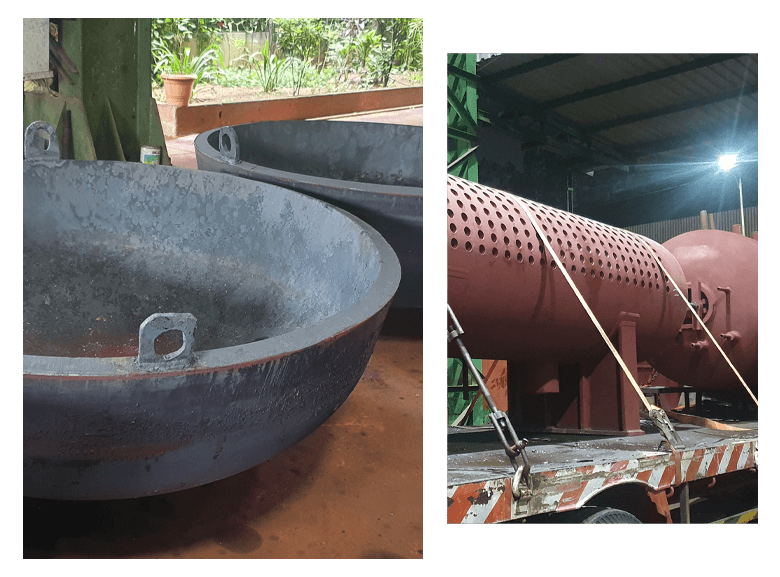

Furnace and Hot forming Activities

Furnace and hot forming activities play a critical role in the metalworking industry, providing precise heat treatment processes that enhance the mechanical properties and performance of metal components. These activities involve controlled heating, cooling, and shaping of metals at high temperatures, resulting in improved strength, durability, and dimensional stability. In this article, we will explore the significance of furnace and hot forming activities, their key processes, and the benefits they bring to the manufacturing sector.

A) Crown, Petal heads, toricones and other petal constructions

- From 6mm to 140mm Thickness

- Height upto 6000 mm

- From 1000 mm upto any diameter

B) Single piece hot formed hemi heads

- From 42mm to 140mm thickness

- From 500 mm and 3000 mm diameter in one piece

C) Flanged and flued Joints (Expansions Bellows)

- From 6mm to 140mm thickness

- From 300mm to 3000 mm diameter in one piece