What is a Baffle Plate?

Baffle plates are structured barriers strategically placed within equipment or machinery to control the flow of fluids or gases. Their primary purpose is to induce turbulence or redirect the flow, thereby improving mixing, heat transfer, or pressure distribution.

Functionality of Baffle Plates

Despite their modest appearance, baffle plates play a crucial role in optimizing the performance of various systems. Some of their functions include

- Directional Control: Baffle plates can redirect flow in specific directions to achieve desired outcomes.

- Particle Separation: In certain applications, baffle plates can assist in separating particles or contaminants from the fluid stream, improving overall system cleanliness.

- Noise Reduction: Properly designed baffle plates can reduce noise levels by dampening turbulence and suppressing vibrations within the system

- Flow Regulation: Baffle plates control the direction and distribution of fluids or gases within equipment, ensuring optimal flow patterns.

- Prevention of Dead Zones: By disrupting stagnant regions within the system, baffle plates minimize the formation of dead zones where fluid exchange is limited.

The Significance of Quality in Baffle Plates

The quality of baffle plates directly influences their performance and longevity. Inferior quality materials or poor manufacturing processes can result in decreased efficiency, premature failure, and increased maintenance costs.

Role of Material Selection

Selecting the right material for baffle plate construction is crucial. Factors such as corrosion resistance, thermal conductivity, and mechanical strength must be carefully considered to ensure optimal performance in diverse operating conditions.

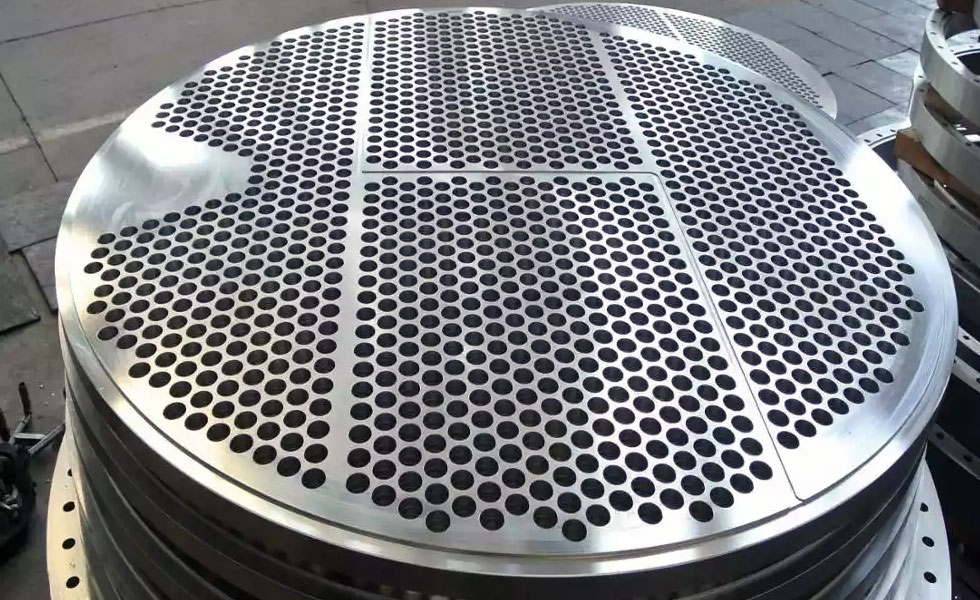

Manufacturing Process of Baffle Plates

Baffle plates are typically manufactured using techniques such as stamping, machining, or welding, depending on the application requirements. Common materials include stainless steel, carbon steel, and various alloys chosen for their specific properties.

Applications in the Precision and Engineering Industry

- Chemical Processing: Baffle plates are used in chemical reactors to promote efficient mixing of reactants and enhance heat transfer rates during exothermic reactions.

- Petrochemicals: In refineries and petrochemical plants, baffle plates help optimize distillation processes by controlling vapour flow and facilitating phase separation.

- Pharmaceuticals: Baffle plates are employed in pharmaceutical manufacturing equipment to ensure uniform mixing of ingredients and maintain precise reaction conditions.

- HVAC Systems: Baffle plates play a vital role in HVAC systems by regulating airflow within ducts, directing air towards specific zones, and reducing noise levels.

- Food Processing: In food processing plants, baffle plates aid in mixing ingredients, controlling temperature gradients, and ensuring consistent product quality.

- Microfluidics: In microfluidic devices used for biomedical research or diagnostic testing, baffle plates help manipulate fluid flow and enhance reaction kinetics.

- Semiconductor Manufacturing: Baffle plates are utilized in semiconductor fabrication processes to control gas flow, maintain uniform temperature profiles, and prevent contamination.

- Aerospace: In aerospace applications, baffle plates are used in propulsion systems, fuel tanks, and cooling systems to optimize fluid dynamics and heat transfer.

Conclusion:

At Rajog Enterprises, we take pride in our responsibility for producing quality baffle plates. With our expertise and commitment to quality, we ensure that every component, including baffle plates, meets the highest standards, thereby contributing to the seamless operation of our clients’ machinery, aiding them to achieve their goals and aspirations within the desired period of time.