Efficiency and Cost Reduction Strategies in Heavy Component Manufacturing

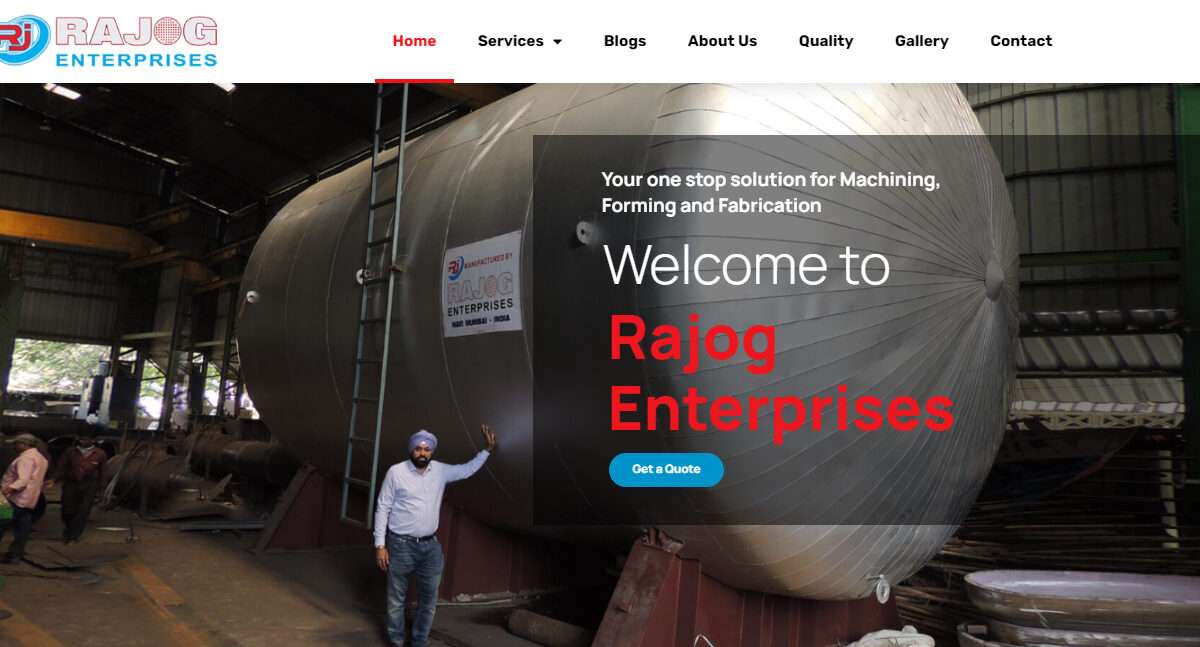

In the highly competitive heavy component manufacturing industry, achieving efficiency and cost reduction is crucial for maintaining a competitive edge and maximizing profitability. Rajog, a leading player in the industry, understands the significance of these factors and has implemented strategic strategies to optimize efficiency and reduce costs throughout their manufacturing processes. In this blog post, we will explore some of the key efficiency and cost reduction strategies employed by Rajog and their impact on their operations and customers.

Lean Manufacturing Principles

Rajog has embraced lean manufacturing principles to eliminate waste and enhance efficiency in their production processes. By implementing practices such as value stream mapping, continuous improvement, and Just-in-Time (JIT) production, Rajog minimizes non-value-added activities, reduces inventory, and streamlines workflow. These lean principles not only enhance productivity but also contribute to significant cost savings by optimizing resource utilization and minimizing lead times.

Process Automation

Automation plays a crucial role in improving efficiency and reducing costs in heavy component manufacturing. Rajog has invested in advanced automation technologies and robotics to enhance their production processes. By automating repetitive tasks, Rajog reduces human error, increases throughput, and achieves higher levels of accuracy and consistency. This automation not only improves overall efficiency but also reduces labor costs and enhances product quality.

Advanced Manufacturing Technologies

Rajog stays at the forefront of technology adoption by utilizing advanced manufacturing technologies. These include Computer Numerical Control (CNC) machining, additive manufacturing (3D printing), and computer-aided design and manufacturing (CAD/CAM). By leveraging these technologies, Rajog achieves greater precision, faster production cycles, and enhanced design capabilities. This results in improved efficiency, reduced material waste, and optimized production costs.

Supply Chain Optimization

Efficiency in heavy component manufacturing is not limited to internal processes but also extends to the entire supply chain. Rajog has implemented supply chain optimization strategies to minimize lead times, reduce inventory carrying costs, and improve overall operational efficiency. By fostering strong relationships with suppliers, implementing just-in-time deliveries, and utilizing demand forecasting, Rajog ensures that the necessary materials and components are available when needed, thus reducing costs and optimizing production schedules.

Continuous Improvement and Employee Engagement

Rajog promotes a culture of continuous improvement and actively engages employees in identifying and implementing efficiency measures. Through regular training programs, process reviews, and employee suggestions, Rajog encourages innovation, problem-solving, and the pursuit of efficiency gains at every level. By involving employees in the improvement process, Rajog harnesses their expertise and insights, leading to enhanced productivity, reduced waste, and overall cost reduction.

Data-driven Decision Making

Rajog leverages data analytics and real-time monitoring systems to make informed decisions and drive operational efficiency. By capturing and analyzing data related to production processes, equipment performance, and quality metrics, Rajog identifies bottlenecks, optimizes machine utilization, and identifies areas for improvement. This data-driven approach enables Rajog to make proactive decisions, minimize downtime, and reduce costs associated with rework or defects.

Conclusion

Efficiency and cost reduction are essential aspects of heavy component manufacturing, and Rajog has implemented various strategies to excel in these areas. By embracing lean manufacturing principles, leveraging automation and advanced technologies, optimizing the supply chain, promoting continuous improvement, and utilizing data-driven decision making, Rajog has achieved significant gains in efficiency and cost reduction. These strategies not only benefit their operations but also deliver value to their customers by offering competitive pricing, high-quality products, and shorter lead times. As the industry evolves, Rajog remains committed to pursuing efficiency and cost optimization to maintain its position as a leader in heavy component manufacturing.